The Hardest Truth I Had to Accept That Made M

The Hardest Truth I Had to Accept That Made Me Stronger...

Motors

I. Introduction

A. Background information on Toyota Motors

B. Overview of products and services offered by Toyota Motors

C. Summary of Toyota Motors’ impact on the global auto industry

Toyota Motor Corporation is one of the largest automobile manufacturers in the world. Founded in 1937, the Japanese multinational corporation has grown from a small auto-manufacturing company to one of the most recognizable names in the industry. Toyota’s success is rooted in its commitment to innovation, quality, and affordability.

The company began as a division of Toyoda Loom Works in 1933, producing spinning machines and weaving looms. After the Great Depression struck, company executives began to consider producing automobiles as a way to stay in business. The first prototype was completed in 1935, resulting in the production of the A1 passenger car—the first vehicle to bear the Toyota name.

Toyota achieved significant growth during the Japanese economic boom of the 1950s and 1960s. In 1957, it established a presence in the United States with the establishment of its U.S. subsidiary. The company also expanded internationally, opening plants in Europe and Latin America. In 1967, it became the first Japanese automaker to produce more than 1 million vehicles in a single year.

Toyota has developed a reputation for reliability and affordability, earning it a loyal customer base. Its vehicles have won numerous awards for quality and safety, including several Car of the Year awards and J.D. Power awards for dependability.

The company remains dedicated to environmental stewardship and has long been an industry leader in hybrid technology. It also strongly supports sustainability initiatives and has established research centers around the world to explore renewable energy sources and conservation methods.

Toyota continues to be an innovator in the automotive industry, developing new technologies that make cars safer, more efficient, and more comfortable than ever before. From its humble beginnings as a loom maker to its status today as a global leader, Toyota has come a long way in its nearly 90-year history.

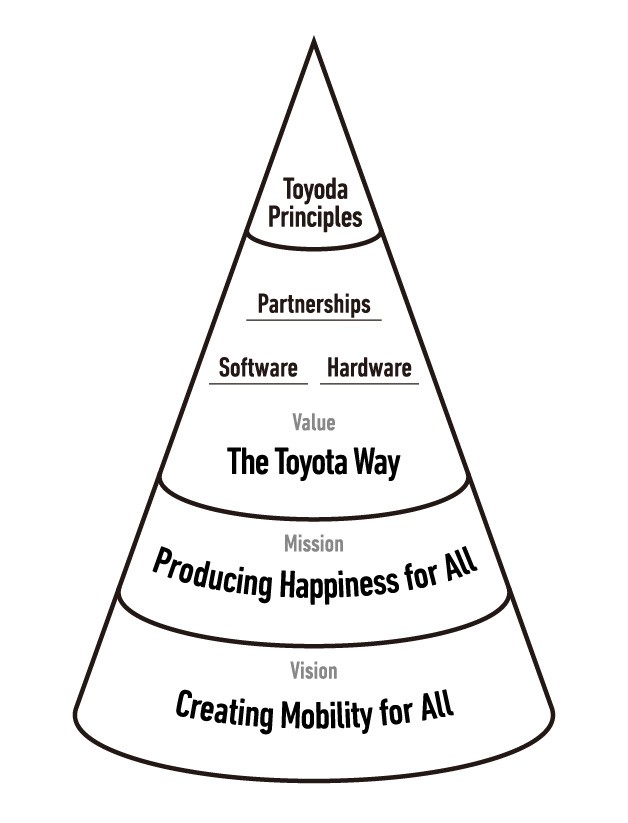

Toyota is one of the world’s leading automotive manufacturers, renowned for their engineering innovation, quality products and exemplary customer service. This success can be attributed to the company’s thesis statement which emphasizes safety, quality and reliability.

For decades Toyota has been setting the standard when it comes to producing dependable, efficient vehicles. This long-standing reputation of excellence can be traced back to Toyota’s mission statement: “To contribute to the sustainable development of society and the planet through creating outstanding vehicle technology.”

These principles are reflected in the company’s many initiatives, which prioritize safety and efficiency while minimizing environmental impact. Toyota’s vehicles are renowned for their dependability, engineering excellence and high safety ratings. The company also puts a huge emphasis on fuel-efficient technology, and has an ongoing commitment to hybrid and electric vehicles.

Toyota also invests heavily in research and development, often pushing the boundaries of what is possible in the automotive industry. The company is always striving to make improvements in areas such as safety, efficiency, emissions and performance. This dedication to innovation has earned Toyota respect around the world.

The company’s values extend beyond the vehicle itself. Toyota is committed to creating a better future for all by investing in sustainability projects and community initiatives. The company works with non-profits and local organizations to promote education and sustainability in the communities they serve.

At its core, Toyota’s thesis statement is geared towards creating a better world for everyone. Through innovative technologies, excellent customer service and a commitment to sustainability, Toyota continues to lead the way in automotive manufacturing.

: The History of a Global Success

II. Toyota’s Early Years: This section will go into detail about the early beginning of the company, from the first few production cars it produced to the first vehicles it debuted in international markets. It will explore how Toyoda Loom Works, founded by Sakichi Toyoda, the father of Kiichiro Toyoda (founder of Toyota), led to the eventual creation of Toyota Motor Co., the impact of World War II on its operations, and the strategic partnerships that Toyota formed during this period.

Toyota Motor Corporation is one of the world’s leading automotive companies. From its humble beginnings as a spinning loom manufacturer, Toyota has evolved into a global powerhouse in both production and technological innovation.

Toyota was founded in 1937 by Kiichiro Toyoda in Japan. In that same year, the company developed its first product, the Type A prototype engine. Throughout the years, Toyota has continually improved and expanded its range of vehicles, leading to the production of the iconic Corolla in 1966 and the Land Cruiser in 1951.

Since its conception, Toyota has been dedicated to technological advancements for a wide range of vehicles. In 1997, Toyota achieved what many automakers had failed to do: mass-produce hybrid vehicles. They did this with the Prius, a ground-breaking car that earned Toyota the 2020 Automotive Technology Prize. They also lead the way with eco-friendly materials in their cars, such as bio-plastics and recycled materials.

Toyota is also known for their dedication to safety technology. In the 1980s, they developed the first Automatic Stability Control system to sense speed, conditions on roads, and driver inputs. They also developed anti-lock braking systems and airbags for all their vehicles. Today, Toyota is one of the few automakers that offers active safety features on all their cars.

In addition to their innovation in vehicles, Toyota has also been a leader in production and manufacturing processes. In the 1950s, they developed a system they called Just-in-Time delivery, where parts are delivered right before assembly, reducing waste and increasing efficiency. Today, they continue to use this system as well as robotics to maintain high standards of production.

Since its inception, Toyota Motor Corporation has been an innovator in production processes as well as vehicle design and engineering. Their commitment to safety, green technologies, and efficiency has helped them remain at the top of the automotive industry for nearly a century. As they continue to evolve, there is no doubt that Toyota will continue to innovate and set new standards for the industry.

Innovation is at the heart of Toyota, the Japanese car manufacturer. It has been part of the company’s DNA since its founding in 1937 when it began producing automated looms. Since then, the company has continuously innovated its vehicles and technologies to stay ahead of the competition and appeal to a global market.

One of the earliest innovations for Toyota was its first gasoline-powered passenger car, the Toyota AA, released in 1936. This marked a major step forward in automotive technology and helped launch Toyota into its current place among the leading automotive manufacturers. The innovation behind this vehicle set the foundation for many more over the years.

The 1950s saw Toyota introducing its first mass-produced car, the Toyopet Crown, which featured a steady, low-speed engine and comfortable suspension. This car was popular with consumers because of its affordability and reliability. This paved the way for more advanced models such as the Corona and Corolla in the 1960s. These cars were hailed for their robust engines, good fuel efficiency, and overall performance.

Toyota has also introduced a number of technological innovations over the years. One example is the Hybrid Synergy Drive system, which combines an electric motor with a gasoline engine to create a more efficient vehicle. This was first introduced in the Prius in 1997 and has since become a common feature in other Toyota models. In addition, the company has also pioneered safety features such as airbags, anti-lock brakes, and advanced driver assistance systems.

These early innovations have helped to make Toyota one of the most successful automotive companies in the world today. Its commitment to innovation has allowed it to remain competitive in a highly competitive market while providing customers with reliable, high-quality vehicles. As Toyota continues to innovate new technologies, it will no doubt continue to lead the way in automotive design and technology for years to come.

’s Influence on the Automotive Industry

III. Toyota’s Contributions to Automotive Industry

A. Introduction to Toyota

B. Developments and Innovations of Toyota

C. Impact of Toyota on Automotive Industry

D. Other Areas Influenced by Toyota

E. Conclusion

When you buy a car from Toyota, you know you are buying quality. With decades of experience in the industry, Toyota has established a rigorous quality control process to ensure that all their vehicles meet or exceed customer expectations. From the assembly line to the showroom floor, Toyota works hard to ensure their vehicles are of the highest standard.

At the assembly plant, Toyota’s quality assurance process begins at the start of production. All parts used in a vehicle must pass strict quality examinations before being used in its construction. Specialists inspect each part for wear, tear, and any potential defects. In addition, each completed vehicle undergoes a series of tests and inspections to ensure it is safe and reliable enough for customers. These tests include checking that all components and systems function properly and that the car meets safety and performance standards.

Toyota also has a rigorous process for ensuring that all parts used in vehicles are up to their high standards. The company requires suppliers to submit samples of parts that meet or exceed given industry specifications. Once approved, the parts are tested in-house to guarantee their functionality and reliability. To ensure optimum performance, the parts are continually tested before being used in production.

After production, each finished vehicle is subjected to even greater scrutiny. Highly trained technicians thoroughly examine each car and look for any potential problems. If something goes wrong during this process, the vehicle is sent back to be reworked or replaced with another car. No vehicle is shipped out until it meets Toyota’s strict quality control criteria.

Finally, Toyota ensures that its cars meet the highest standards of quality while on the showroom floor. They continually monitor customer feedback on a daily basis and act quickly to resolve any issues that may arise. Plus, they have a team of dedicated customer service staff available who can help customers with any questions or problems they may have with their vehicles.

In today’s competitive automotive market, quality control is more important than ever. Toyota recognizes this and takes measures to make sure that each car they build upholds their high standards of quality. Whether you purchase a new car or an older model, you can rest assured it has been tested and inspected rigorously by Toyota’s quality assurance team.

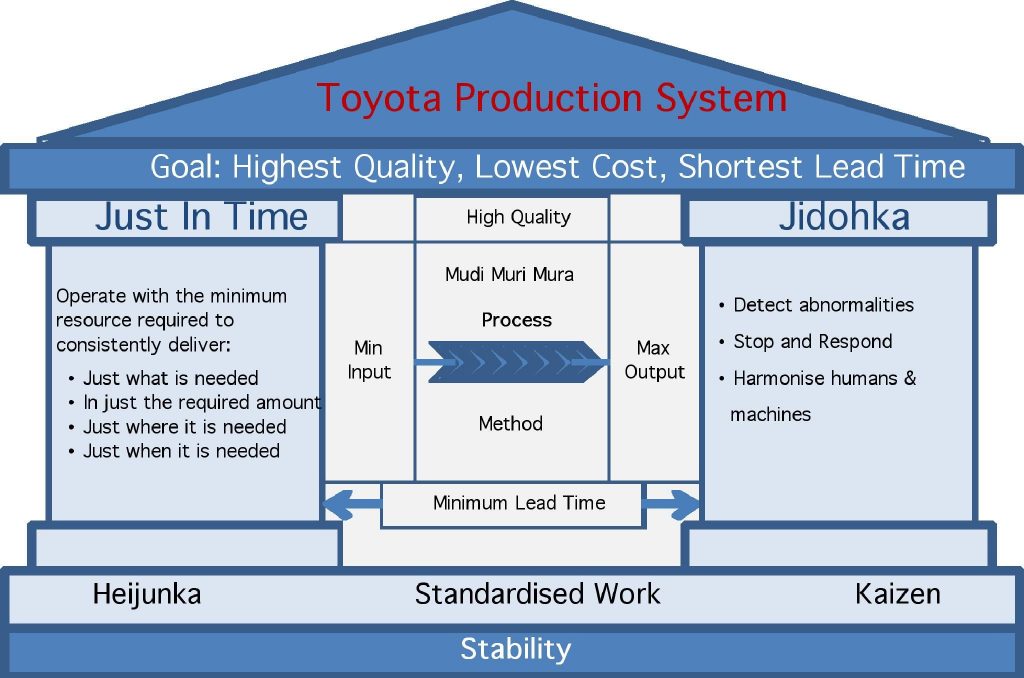

The automotive industry has been around for centuries, and it has seen its fair share of changes in recent years. One of the most significant changes that has emerged is the concept of Lean Manufacturing, pioneered by Japanese automotive giant Toyota. Lean Manufacturing is a form of production management that places emphasis on efficiency and quality. It is based on the principle of eliminating waste without compromising safety or reliability. Toyota is widely credited with ushering in the new era of Lean Manufacturing, and they have had significant success in doing so.

At the heart of Lean Manufacturing is the practice of reducing waste and eliminating unnecessary processes to streamline production and reduce costs. This is best exemplified by Toyota’s “Just-In-Time” (JIT) manufacturing system, which emphasizes producing only components needed for a particular production run. By eliminating stockpiling of items that may not be used, Toyota was able to significantly reduce costs while maintaining high-quality standards.

Another key element of Lean Manufacturing is focusing on continuous improvement. This is typically done by using customer feedback to identify areas where production processes can be improved upon. Toyotas Kaizen system, which encourages employees to regularly suggest improvements, ensures that Toyota remains at the cutting edge of production technology.

Toyota has also implemented a number of other Lean Manufacturing initiatives such as using automation to reduce labor costs, relying heavily on vendor managed inventory systems, and using total quality management systems to ensure the highest quality products. By utilizing these strategies, Toyota has been able to improve production efficiency and increase customer satisfaction while maintaining lean production methods.

Toyota’s success with Lean Manufacturing techniques has been significant. The company has seen dramatic increases in efficiency and cost savings with its JIT system, and its Kaizen system ensures that Toyota remains at the forefront of production innovation. In addition, its use of automation has allowed Toyota to produce more vehicles with fewer resources, making it one of the world’s most successful automotive companies. By embracing Lean Manufacturing principles, Toyota has become a leader in automotive production.

Just-in-time production (JIT) is a type of production system that has been widely used by Toyota to improve their manufacturing operations and reduce cost. JIT is an inventory control system that seeks to reduce waste and inefficiencies in the production process by producing only what is needed, when it is needed, and in the amount needed.

In the JIT system, parts are delivered just in time for assembly, allowing Toyota to minimize storage costs and the amount of inventory on hand. It also allows them to quickly adjust to changes in customer demand. Thus, Toyota does not need to invest large sums of money in equipment and components in advance.

Toyota developed the JIT concept as a way to counter the inefficiencies caused by the traditional mass production system. By focusing on minimizing waste and using fewer resources, Toyota could reduce costs and increase production speed. Additionally, the JIT system ensures that all parts are of consistent quality and helps to detect any defects during the manufacturing process.

The use of JIT production has been integral to Toyota’s success as a manufacturer. In addition to reducing costs, JIT has allowed Toyota to be more flexible and nimble in responding to customer needs. It has also enabled them to quickly identify and address problems in their production process.

In conclusion, Just-in-time production has been an integral part of Toyota’s success. Its use has allowed Toyota to reduce costs, increase production speed, and quickly respond to customer needs. This has allowed Toyota to remain competitive in the automotive industry.

’s Impact on the Environment

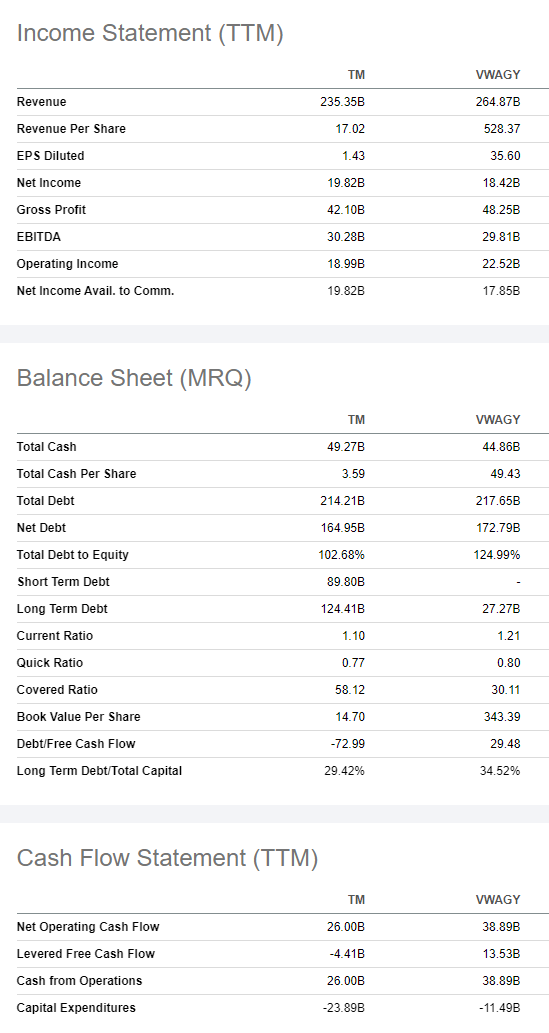

IV. Toyota’s Impact on the Global Economy

a. Positive Impacts

b. Negative Impacts

c. Conclusion

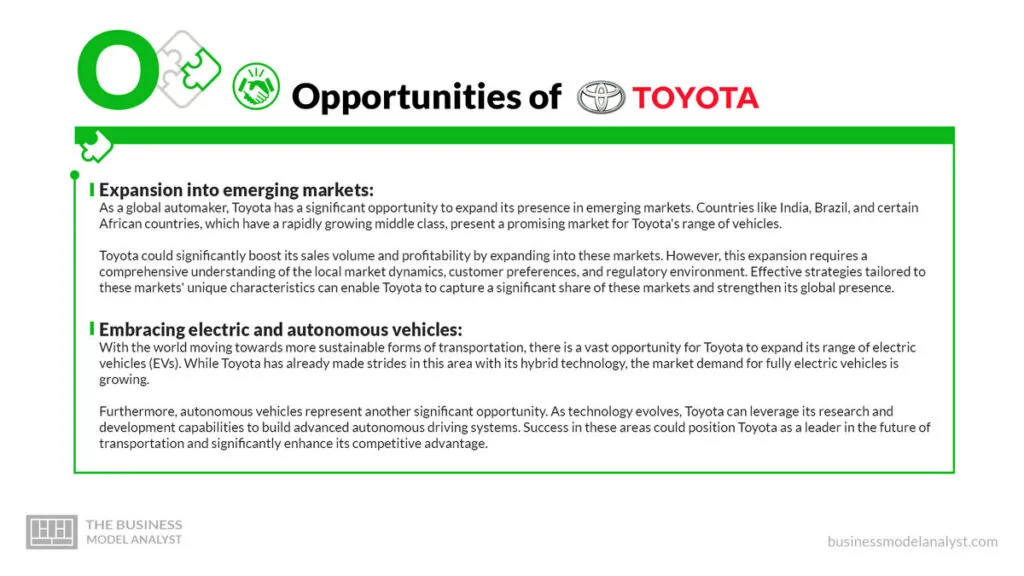

The Toyota Motor Corporation has been expanding into global markets for decades, and its expansion efforts continue to this day. Toyota’s ability to expand internationally has been one of the key drivers of its success, allowing it to become one of the most well-known, successful, and profitable automotive companies in the world. By expanding into global markets, Toyota has been able to capitalize on the unique advantages of each market it has entered and maximize its profits.

One of the primary reasons for Toyota’s success in global markets is its commitment to quality. Toyota’s dedication to quality has been evident in every product it produces. From the design process to production and assembly, Toyota strives to produce the highest quality vehicles possible. This focus on quality ensures that Toyota cars provide safe, reliable transportation for customers all over the world.

In addition to emphasizing quality, Toyota’s expansion efforts have also included a strong focus on customer service. In order to effectively reach customers across the globe, the company has implemented an effective customer service network. It has established customer service centers in various countries around the world, and provides customers with both online and telephone support. These centers are staffed by knowledgeable representatives who are prepared to answer customer questions and help them with any issues they may have.

Furthermore, Toyota has also leveraged innovation and technology in order to provide customers with the latest features and technology available. For example, the company has developed a number of hybrid vehicles that utilize both gasoline and electric power in order to reduce fuel consumption and emissions. Additionally, Toyota has also developed advanced infotainment systems as well as other driver-assistance technologies that help make driving efficient and enjoyable for its customers.

Finally, Toyota has also made sure to consider local regulations when it comes to their expansion efforts. By understanding the regulations of each particular market they enter, they have been able to ensure that their vehicles meet all safety and environmental standards of each country. This has been a crucial factor in allowing Toyota to become a major player in global markets.

Overall, Toyota’s expansion into global markets has been an important part of its success story. By utilizing quality standards, customer service networks, innovative technology, and local regulations to their advantage, Toyota has been able to establish itself as a major player in international markets. With its ongoing commitment to global expansion, Toyota is likely to remain a leader in the automotive industry for years to come.

Toyota is one of the world’s largest companies and has had a great impact on the global economy. This Japanese automotive giant has established itself as one of the biggest players in the world car market and has become a symbol of success for many car manufacturers.

Toyota has been able to successfully compete in the global market by producing high-quality, reliable, and efficient vehicles that are affordable and accessible to everyone. This company has generated billions in revenue over the years, and its economic contribution to the world is undeniable.

The company has employed thousands of people all over the world, providing them with well-paying jobs that have allowed them to support their families and play an active role in their local economies. In addition to this, Toyota’s profits have enabled them to invest in research and development, which has led to technological advancements that have benefited society.

The company’s vehicles have become a popular choice for consumers due to their high quality, reliable performance, and fuel efficiency. This has resulted in an increase in demand for Toyota products across the globe and has contributed significantly to the growth of the automotive industry.

Furthermore, Toyota has established a presence in many countries around the world through their branches and subsidiaries. This has allowed them to expand their market reach while also stimulating local economies. In addition, Toyota’s investments in charitable organizations have further helped communities grow by providing them with resources and education opportunities.

Toyota’s influence on the global economy is undeniable. The company is responsible for creating job opportunities, stimulating economic development, increasing demand for their products, and investing in charities. All these factors have made Toyota one of the most successful companies in the world and its impact on the economy will continue to be felt for years to come.

‘s Production System

V. Conclusion

The Toyota Production System is a comprehensive set of principles and processes that have enabled Toyota to become one of the most successful automotive companies in the world. By implementing this system, Toyota has been able to significantly reduce costs and improve quality and productivity. In addition, the Toyota Production System has allowed the company to create a safe and rewarding working environment for its employees. As a result, it can be concluded that the Toyota Production System has been a major factor in Toyota’s success.

Toyota, founded by Kiichiro Toyoda in 1937, is one of the world’s largest automotive manufacturers. It is also renowned for its commitment to sustainability, innovation, and quality. Toyota’s success can be attributed to its long-term strategy that has been focusing on producing reliable, cost-effective, and dependable cars that meet customer needs. Toyota has made significant contributions to society by producing advanced and efficient vehicles that are safer and more fuel-efficient, creating quality jobs, advancing technology, and providing customer service.

One of Toyota’s major contributions is its dedication to producing vehicles that are both fuel-efficient and safe. Toyota has led the way in developing hybrid vehicles which reduce fuel consumption and emissions, as well as in developing comprehensive safety systems such as Vehicle Stability Control (VSC). Additionally, Toyota’s commitment to quality has resulted in it leading the way in producing vehicles that are reliable and durable.

Toyota has also been a major provider of jobs in both direct and indirect employment opportunities. As of 2020, Toyota provided nearly 1 million jobs around the world. The company has also invested heavily in training and development to ensure its employees have the skills and experience to meet customer needs.

Toyota has also been a leader in advancing technologies for the automotive industry. This includes its recent introduction of autonomous vehicle technology, which promises to revolutionize the way we drive. The company has also pioneered hydrogen fuel cell technology, helping to reduce carbon emissions and improve energy efficiency.

Finally, Toyota is renowned for providing excellent customer service. Toyota’s customer service centers are located all around the world, providing customers with the best possible service when it comes to vehicle maintenance or repairs. This commitment to customer satisfaction has helped build a loyal following of customers who trust the brand.

In conclusion, it is clear that Toyota has made significant contributions to the automotive industry and society in general. It has produced fuel-efficient and safe vehicles; created jobs; advanced technology; and offered excellent customer service. As such, Toyota will no doubt remain a major player in the automotive manufacturing industry for years to come.

The automotive industry is constantly evolving and changing, which makes it difficult to keep up with the times. One of the major players in this industry is Toyota, which has seen a great deal of success over the years. The company has consistently pushed the envelope of automotive technology, resulting in a wide array of advanced vehicles. This innovation has had a major impact on the automotive industry as a whole, with other manufacturers often following suit with their own advancements.

Toyota’s commitment to automotive innovation has led to the development of several breakthrough technologies. Perhaps the most famous of these is the company’s Hybrid Synergy Drive system, which combines gasoline and electric engines. This innovation led the way for other automakers to follow and helped spread the use of hybrid vehicles around the world. Toyota also has pioneered the use of fuel cells, driving range, and electric vehicles, all while working towards a more sustainable future.

In addition to its technological contributions, Toyota has also had an influence on safety standards. The company was one of the first to introduce safety features such as seatbelts and airbags. This commitment to safety has been reflected in its vehicles, with safety tests showing that some of Toyota’s models are among the safest on the road today.

Throughout its history, Toyota has been pushing the boundaries of automotive technology and safety standards. In doing so, the company has had a major impact on the automotive industry as a whole. From pioneering hybrid and electric vehicles to introducing countless safety features, Toyota has changed the way we think about cars and transportation today.

The global economy is highly interconnected and complex. When an individual company makes decisions or experiences a disruption, it can have an effect on the entire world economy. This is especially true for large multinational companies, such as Toyota. As one of the largest automakers in the world, Toyota’s decisions and disruptions can create a ripple effect that reaches far and wide.

Toyota’s impact on the global economy is difficult to overstate. As one of the top ten companies in terms of revenue, it controls 12% of the global automotive market share and is responsible for 5.8% of all global vehicle production. This means that any disruption in production or pricing can have an immediate and drastic effect on the supply chain and other automobile manufacturers. Similarly, any change in Toyota’s public image can affect consumer sentiment towards the automotive industry as a whole.

The company’s decisions and disruptions also affects employment rates around the world. Currently, Toyota employs more than 374,000 people globally—many of whom rely on Toyota for their livelihoods. Furthermore, it supports a plethora of additional jobs related to its supply chain. Any significant shift in its production or business decisions can create waves that negatively affect the economy.

Beyond its economic contributions, Toyota also has a large social footprint throughout the world. The company has made significant donations to emergency relief funds and has invested heavily in initiatives designed to reduce carbon emissions from vehicles. This can have a positive impact on environmental protection efforts around the world and help to offset its contribution to pollution caused by vehicle manufacturing and operation.

In conclusion, Toyota’s influence on the global economy is immense. Its decisions and disruptions can lead to immediate effects on the supply chain, employment rates, and consumer sentiment, as well as long-term effects on environmental protection efforts worldwide. While some of these effects are hard to predict, it’s clear that if Toyota continues to operate responsibly, it’s likely to remain one of the biggest names within the automotive industry for years to come.

You cannot copy content of this page